As technology continues to advance, the demand for materials that can withstand extreme environments is ever-increasing. One solution to this challenge is the development of a 3D printable alloy specifically designed to thrive in harsh conditions. This innovative material offers a unique combination of strength, durability, and resistance to high temperatures, making it ideal for applications in industries such as aerospace, automotive, and manufacturing.

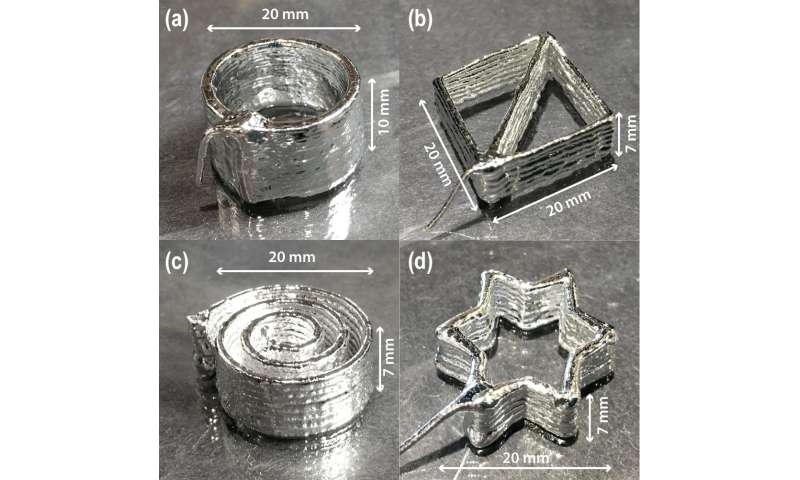

With the ability to be created through additive manufacturing processes, this alloy opens up a world of possibilities for engineers and designers looking to push the boundaries of what is possible in extreme environments. By leveraging the flexibility of 3D printing, complex geometries and structures can be easily fabricated, allowing for customized solutions that are tailored to specific needs.

One of the key advantages of this 3D printable alloy is its exceptional heat resistance, making it ideal for use in environments where temperatures can reach extreme levels. This feature allows for the creation of components that can withstand intense heat without compromising on performance, making it a valuable asset for industries that operate in challenging conditions.

In addition to its heat resistance, this alloy also offers superior strength and durability, ensuring that components can withstand the rigors of extreme environments without succumbing to wear and tear. This high level of performance makes it a reliable choice for critical applications where failure is not an option.

Furthermore, the versatility of this 3D printable alloy allows for the creation of lightweight yet durable components, reducing overall weight and improving efficiency in various applications. This can lead to cost savings and improved performance, making it a highly attractive option for industries looking to enhance their capabilities in extreme environments.

In conclusion, the development of a 3D printable alloy designed for extreme environments represents a significant advancement in materials science. By combining strength, durability, and heat resistance, this innovative material opens up new possibilities for industries looking to push the boundaries of what is possible in challenging conditions. With its ability to be customized through additive manufacturing processes, this alloy represents a promising solution for a wide range of applications in aerospace, automotive, and manufacturing.